As part of our growth investments in existing fields, the Daiwabo Group is dedicated to R&D and development of the platform. We are working on this in line with the characteristics of the IT Infrastructure Distribution Business and Industry Machinery Business, respectively.

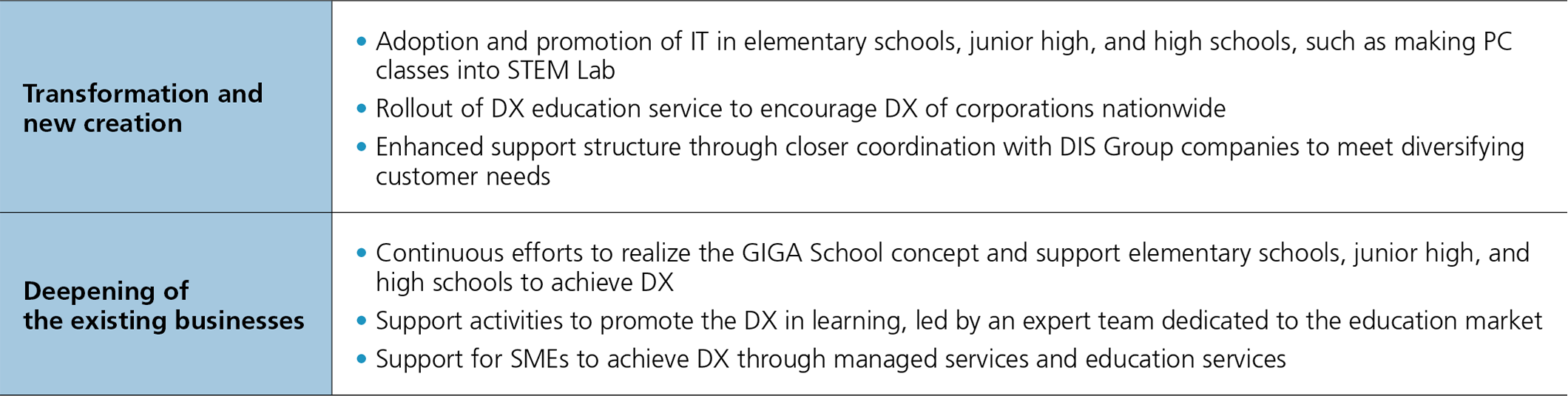

In the IT Infrastructure Distribution Business, strong partnerships with various manufacturers and IT vendors allow us to provide advanced and global cloud services that fulfill the diverse needs of users, contributing them to achieve DX. Simultaneously, we strive to improve the efficiency and safety of social infrastructure and public services, reduce environmental impact, and promote social inclusion, all aiming to build a sustainable society. Our efforts to assist companies, especially small and medium size enterprises (SMEs), in achieving DX include various managed services to support IT operations and management designed to resolve workforce shortages and improve the productivity on the sales partner and user side, as well as education services for the training of DX-ready professionals to promote the nationwide digital transformation. Our cloud services provide a diverse range of solutions and support, including hybrid cloud solutions with on-premises integration, as cloud computing continues to be utilized in increasingly versatile scenarios. We encourage the optimal cloud usage tailored to the users’ environment while promoting the development of new business models in combination with our sales partners’ core businesses. Through these efforts, we provide opportunities for value creation in business and service design for our sales partners and users.

In the machinery and software development, we ensure that our customers’ needs for existing products are fulfilled and necessary safety measures are implemented. In recent years, we have been putting more focus on responding to the needs from the aerospace and wind power generation industries: for example, an automatic tool changer compatible with high-pressure and high-capacity coolant, aiming to provide the aerospace industry with enhanced cutting performance for difficult-to-cut materials; structural changes to large-sized lathes for the wind power generation industry to improve transportation efficiency; a chip detection system using AI technology; and a carton refilling device responding to labor-saving needs. In this way, we will continue to make technological developments and improvements to accurately grasp market needs.